Textile Ducting vs Traditional Metal Ducting

Textile ducting is best thought of as a diffuser that brings the supply air into the room before discharging it in a suitable air pattern. It works alongside rigid ducting, replacing only the ducts and diffusers in the room. Meanwhile, transporting the air from a source (such as an air handling unit) to the room is typically done using standard steel ductwork.

What are the advantages of using fabric diffusers instead of rigid ducts and diffusers?

Some of the main advantages of using textile ducting over traditional metal ducting are its efficiency, cost-effectiveness, sustainability and versatility.

Efficient ventilation with textile ducting

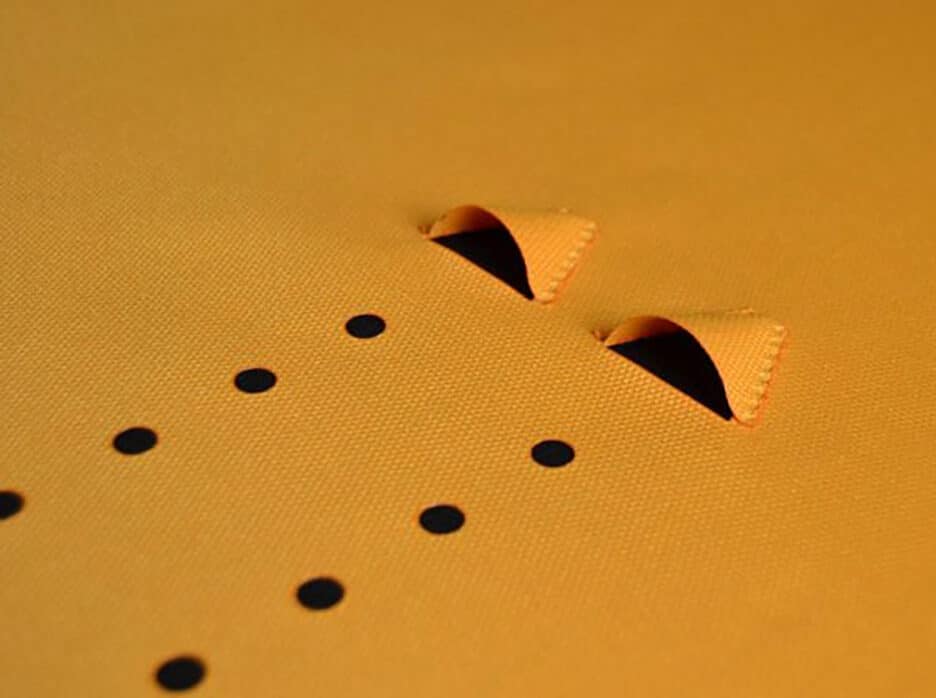

Textile ducting can be an efficient alternative to traditional metal ducting. Since it is flexible and always designed specifically for each application, it can be used to maximise efficiency in the system. Most rigid ducts rely on a limited number of diffusers dotted around a room to provide all the required airflow, whereas with fabric ducts the entire area of the duct can have microperforations, laser-cut perforations or nozzles to diffuse the air anywhere in the space. The air can be directed exactly where it is needed to achieve the level of air movement, heating or cooling required by the project. What’s more, with textile ducting there is no need to balance the system – the size and position of the diffusers on the fabric duct is selected and calculated based on the air flow rate and supply air parameters.

Cost-effectiveness

The textile ducting alternative is often significantly cheaper than the equivalent metal ducting. There are three main reasons for this:

1) the fabric material itself is typically cheaper than other options such as galvanised steel; and 2) a fabric duct uses less material overall because the exact amount of fabric is calculated and cut for the design, and 3) the textile ducting installation requires less secondary steelwork due to the much lower weight of the ducts themselves.

Sustainability

Textile ducts are an excellent choice when it comes to enhancing the green credentials of a project. Each fabric duct requires a lot less polyester material than the steel it would need for an equivalent rigid duct. As a result, the embodied carbon content is also much lower – 1 m² of sheet steel contains 18.6 times more embodied carbon than 1 m² of polyester material used for textile ducting. Prihoda fabric ducting is also available in recycled material, which is identical to the classic material; the only difference is that it is made from post-consumer recycled water bottles.

Versatility

One of the biggest advantages of using textile ducting over traditional rigid ducts is its inherent versatility. Fabric ducting can be made in a range of shapes and there are no stock parts – everything is designed especially for the task at hand, which means that any challenging requirements can be ironed out at the design stage. Installing in tight spaces, underfloor ventilation, displacement cooling and many other options are easily achievable with fabric ducting. Textile ducting’s lower weight also means that it needs less mounting material than rigid ducting, making installation easier and more versatile. There are multiple mounting options to suit almost any type of ceiling or roof.

Visit the Prihoda UK Ltd website for more information on Textile Ducting vs Traditional Metal Ducting