Engineering Without the Nightmares

October might be a month for ghosts, ghouls, and jump scares, but in the world of fluid transfer, the real fright comes from unexpected downtime. When equipment fails, when a line seizes, a joint leaks, or a connection wears out too soon, the consequences can be far scarier than anything you’ll see on Halloween night. Every minute of disruption adds cost, safety risk, and stress to your operation, turning what should be a smooth, controlled process into a nightmare.

That’s why Swivel Joints play a vital role in keeping your systems running efficiently and safely. From Loading Arms and Hose Reels to Storage Terminals and Chemical Transfer Systems, these components quietly do the hard work of managing movement, preventing twisting, and reducing stress on your equipment.

Compact Swivel Joints – Conquering Tight-Space Terrors:

Compact Swivel Joints are the perfect solution when space is limited but reliable movement is critical. Designed for confined areas, they allow smooth rotation while reducing stress on hoses and connections. By keeping fluid transfer consistent and preventing maintenance nightmares, these joints ensure your operations remain efficient and free from the downtime that can haunt even the best-planned systems.

Swivel Joint Scissors – Twisting Through Tight Corners:

Swivel Joint Scissors are designed for installations with tricky angles or long spans, where hose stress and misalignment can creep in like hidden ghosts. By allowing smooth multi-directional movement, they keep hoses and pipes flowing reliably, preventing the kind of failures that can haunt maintenance teams. Even in complex layouts, these joints ensure your systems operate efficiently, keeping downtime and surprises firmly at bay.

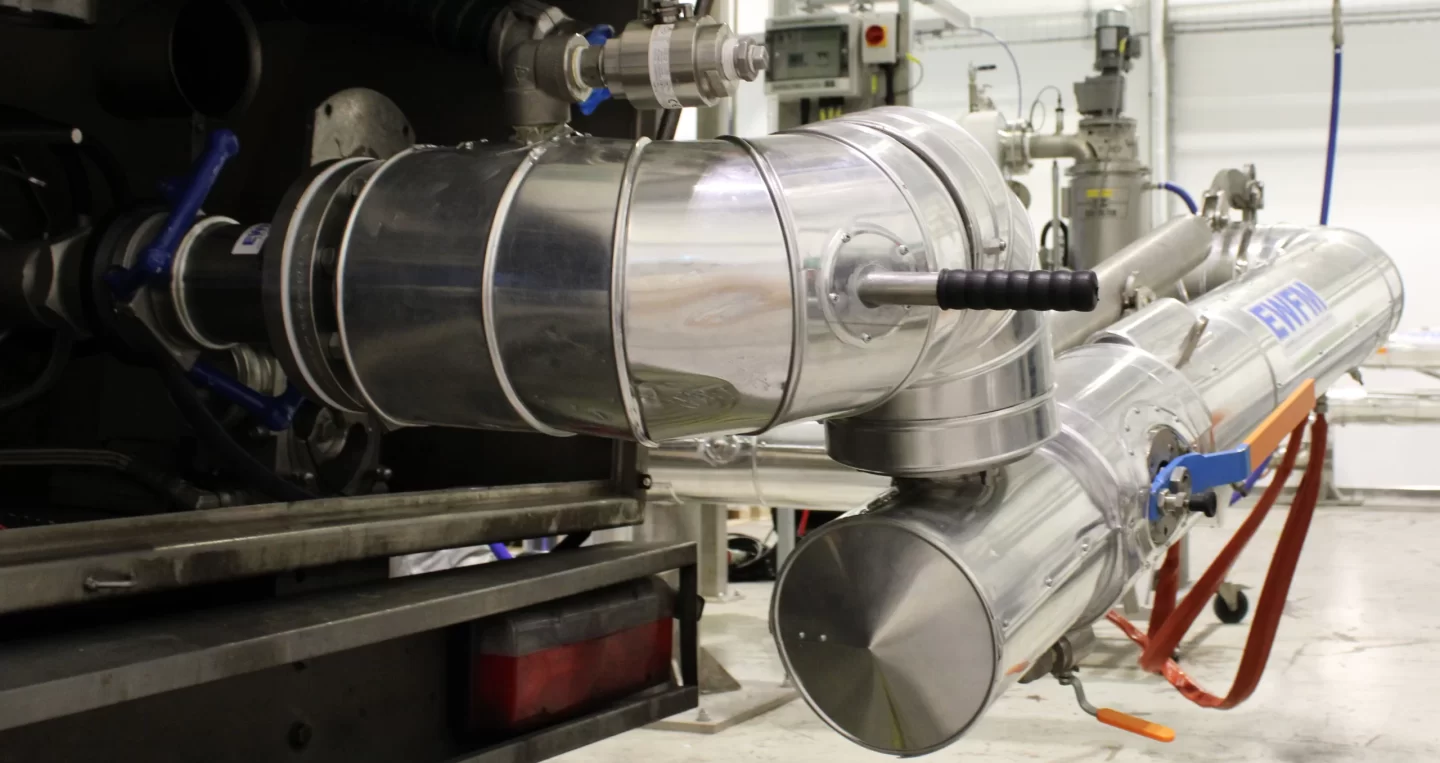

Multiport Rotary Unions – Keeping the Flow from Turning into a Nightmare:

Multiport Rotary Unions are built to handle multiple fluid channels in a single rotating joint, eliminating the tangled connections that can create serious operational headaches. By keeping flow paths separate and controlled, they prevent leaks, pressure loss, and unexpected downtime that could haunt your system. These joints make complex fluid handling safer and more reliable, ensuring your operations run smoothly without any frightening surprises.

Large Bore Swivel Joints – Facing the Big Frights:

Large Bore Swivel Joints are built for high volume transfers and heavy duty applications, where leaks or failures can create serious operational nightmares. Their robust construction ensures smooth rotation and reliable flow, even under extreme pressure or with large hoses and pipes. By keeping your systems moving efficiently, these joints help you avoid unexpected downtime and the maintenance scares that can disrupt large-scale operations.

From Compact Swivel Joints to Scissor designs, Multiport Rotary Unions, and Large Bore options, our extensive range covers every industrial application and fluid transfer challenge. Each joint is built to keep your systems running smoothly, prevent unexpected downtime, and make maintenance a stress-free experience, no tricks, just reliable performance.

If you want to ensure your operations stay efficient and free from surprises this Halloween, get in touch with our team today to find the right Swivel Joint solution for your needs.

Visit the EWFM website for more information on Engineering Without the Nightmares